Free-flowing or flexible goods can be gently fed at a high pace using gravimetric feeding or metering.Gravimetric feeders that are comparatively straightforward and incredibly dependable, weigh belt feeder offer precise feeding and effective process monitoring. They can be employed as meters, batches, or feeders. For feeding friable stuff that may be harmed by traditional feeding techniques, or for erratic flow metering in situations with restricted headroom, the SWB is the ideal choice. Large amounts of bulk material with various flow characteristics can be handled by this small gravimetric feeder.

Interactive areas

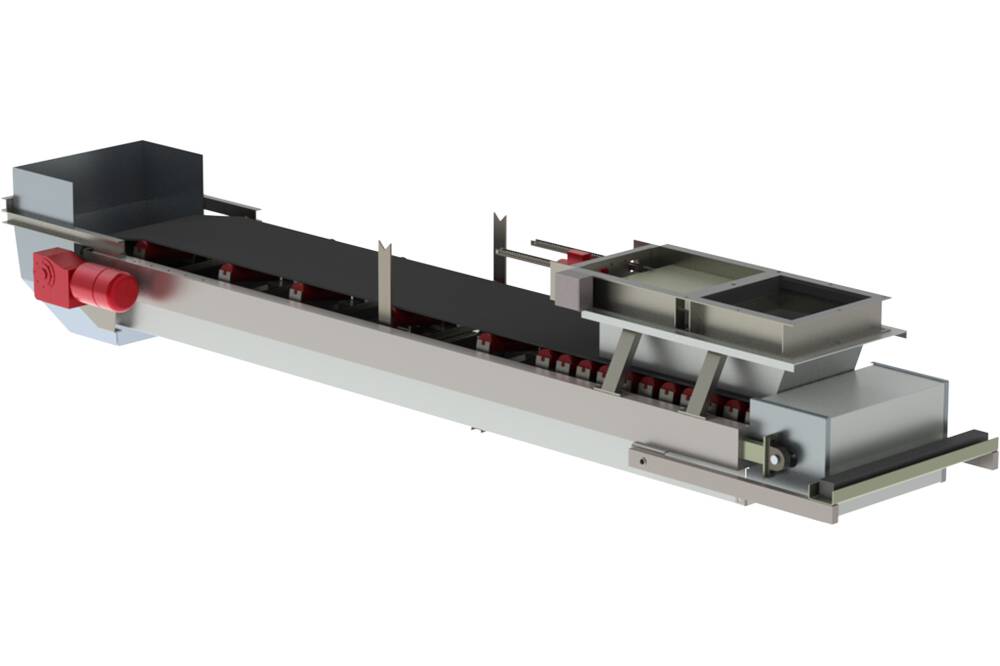

Continuously regulated gravimetric feeding of large volumes is accomplished with the Smart Weigh Belt Feeder SWB. Feeding or weighing data into an ongoing procedure is the most common use. The SWB may also feed material into an automated system by using a separate control program.Weigh belt feeders work well with generally free-flowing materials that don’t require confinement because of this feature. A significant advantage over other feeding systems, such as the screw feeder, is the delicate material handling provided by the SWB for certain materials.

- Sources of carbs: rice, flour, and wheat

- Dense, bulky stuff, such as fruits and vegetables

- Chop fragile things (such as popcorn, freezing fruit, and frozen veggies)

- Bulk materials with lower melting temperatures, including fat flakes

- Bulk solids that are more abrasive due to their lower friction coefficient.

The design elements

Weigh belt feeder may achieve high rates without compromising compactness because it functions by continually weighing material on the smaller conveyor belt’s moving bed and then modifying the belt’s speed to give the necessary displacement.

Two rate categories comprise the models that are now available:

SWB-300 and SWB-600 are mid-rate

SWB-650, SWB-800, and SWB-1000 are high-rate

Commercial-grade and certified-quality belt scales

Specifies a wide range of requirements, such as high accuracy for loading and unloading systems, control transfer and NTEP approved variance (0.10% to 0.125%), and inventory and process requirements monitoring (0.25% to 0). .5%), and various stone and joint applications (0.5% to 1%), are addressed through our manufacture of conveyor belt scales and weighing equipment.Our conveyor belt scales are used in extreme situations and is among the most difficult production settings by clients in the coal, fertilizer, mining, ore, and copper sectors. Our belt scales are used for light-loading applications in a variety of other sectors, such as the processing of tobacco and pulp and paper. These examples show how, with few adjustments, our conventional designs can accommodate a broad spectrum of belt-size applications.

With our conveyor, we provide several unique options.Conveyor belt scales are used for scale pricing and weighting systems; they are intended for light-scale handling of commodities including MSW, biomass, wood chips, sawdust, and tobacco.